bull nose end mill vs flat end mill

Bull nose end mill vs flat end mill Saturday February 26 2022 Edit A vertical pistol grip places your hand in perfect position from the bench or prone to manipulate the tang safety and optimize reach to the trigger. AISI H13 52HRC Cutting length.

Flat end mill is the end mill with flatsquare end.

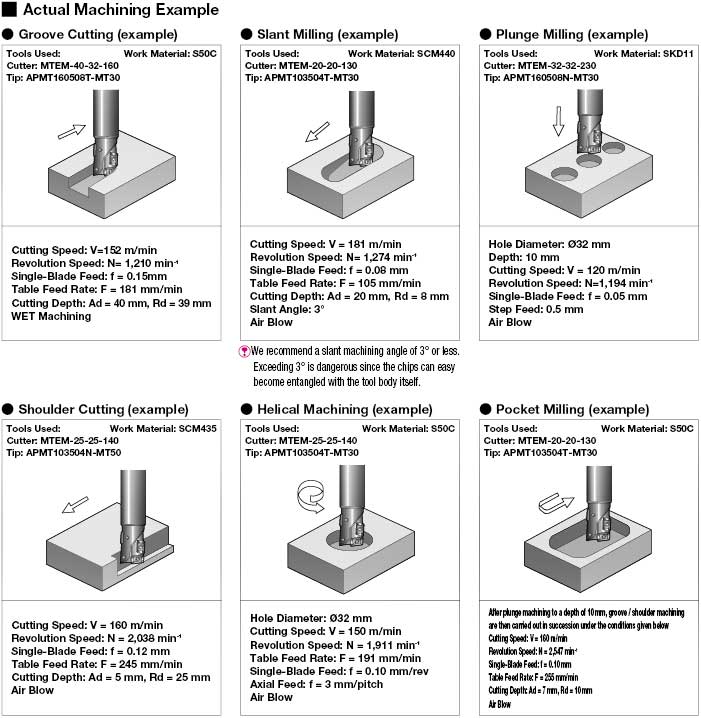

. Flat bottom inserts cut effective Z-level and plunge milling with a full 90-degree side wall and multiple standard corner radii. Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity. Competitor A R02 The R part got out of shape.

Bull-nose end mills are often used to mill molds plastic injection molds die cast molds etc 2. Bull-Nose Corner Radius End Mill. LEARN MORE edp.

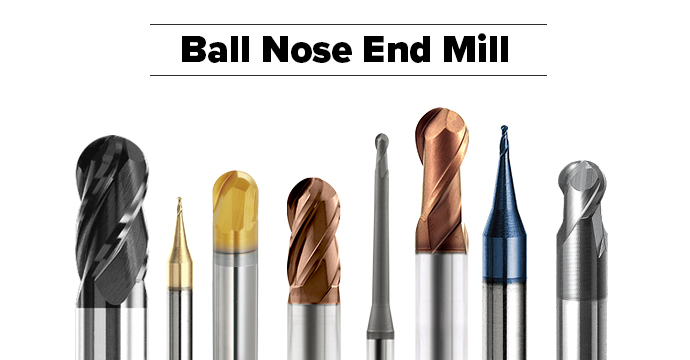

There are also bull nose end mills these have radiused corners that are smaller than the radius of the cutter. End mills come in a variety of shapes. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball nose at the tip of the tool.

For longer tool life and a better finish in general purpose milling applications these solid carbide end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel end mills. Ball nose end mill is a kind of tool which is assembled on the milling machine with the cutter similar to the ball head and is used for milling various curved surfaces and arc grooves. Similar to square end millsflat end mills but these have a round cutting edge also known as bull nose not to be confused with Ball nose as mentioned above.

Since they combine a flat bottom with round corners they can create flat-bottomed pockets with rounded corners at once without changing tools. When one end wears out turn the tool around for a sharp edge. This enables a cnc machine to machine complex flowing shapes to reproduce decorative attractive projects.

R02 Ball nose end mill Workpiece. Ø062-500 Cylindrical 2 Flute 30 Helix. Ball nose end mill-R15 Competitors ball nose end mill-R15 small diameter end mill series achieves high R accuracy and runout accuracy.

Cobalt Steel Ball End Mills with Two Milling Ends. The flat end mill is widely used in groove processing side processing and step surface processing. Ad Browse discover thousands of brands.

End mills in different number of flutes. Read customer reviews find best sellers. The ball has a radius with its center point at the center of the end mill so the radius is always 12 of the diameter.

The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Ball end mills will leave smaller scallops for the same stepover. Competitor B suffered from tool breakage.

The radius of its round corner is smaller than the cutting radius. The compression end mill creates a smooth surface on top and bottom which is perfect for pre-laminated woods. Often used for slotting and pocketing cuts in mold and die making these end mills have a 90 profile and rounded corners which reduce flute breakage and chipping.

A ball end mill is not the same as a corner radiusbull nose end mill. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. Channeling 4 Ramping 4.

2005015 18-1-12---SQ - 00200. Sterling Edges backdraft bullnose inserts are standard for profiling on draft walls requiring chip clearance during the cutting. Ball Nose End Mill.

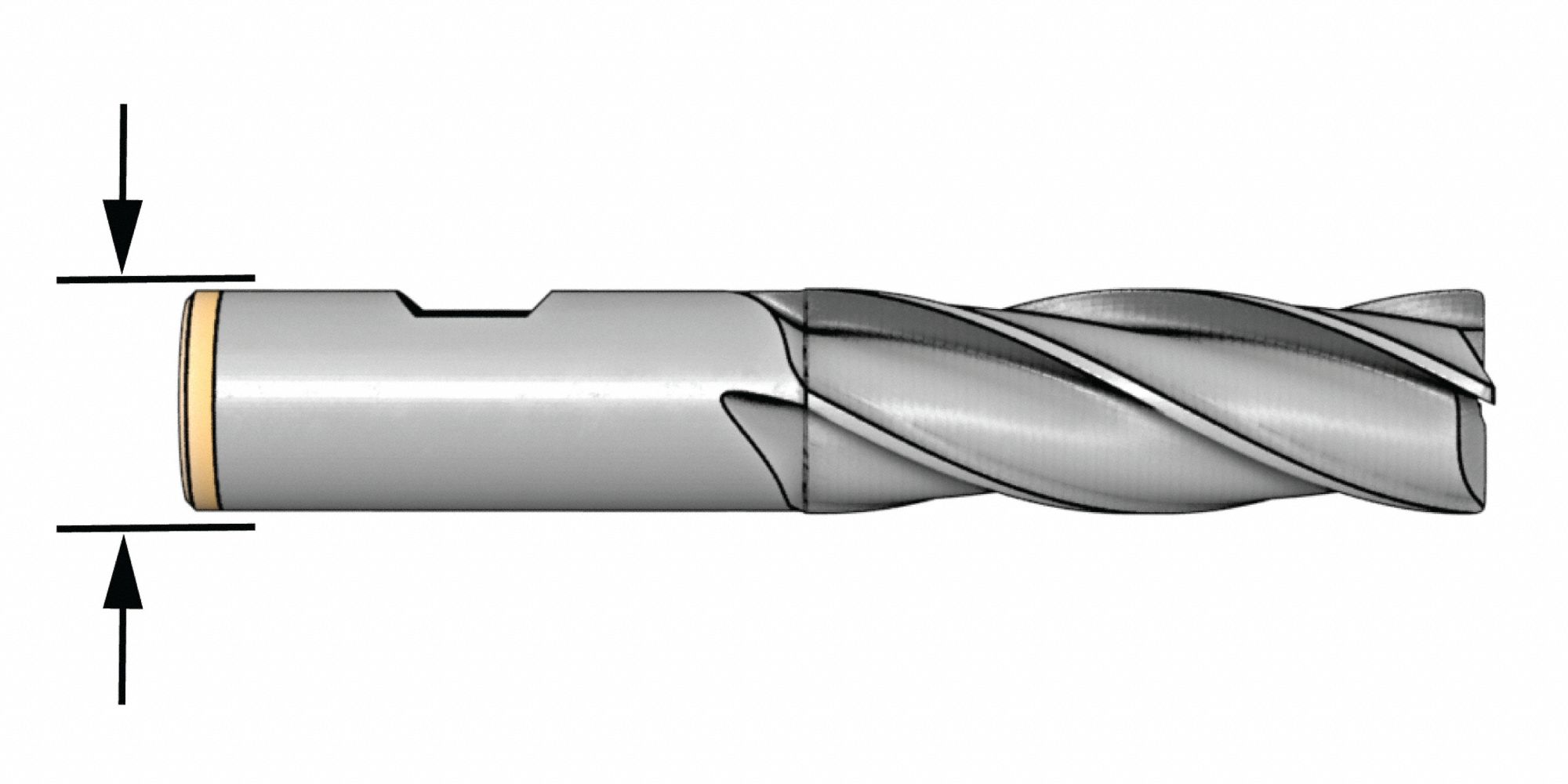

It is a general end type for rough millingmore economic compared with ball end mill and corner radius end mill but it is not suitable for machining in speed as high as other two type end mills because too high rotation and feed rate may cause sharp corner blade to break. Bull-nose end mills are often called corner radius end mills and are a combination of fishtail and ball-nose. Ad Significantly Increase Productivity Reduce Costs in Just Minutes With Our New Service.

They are usually made from high speed steel or cemented carbide and have one or more flutes. Also called corner radius end mills this type of cutter is a combination of fishtail and ball-nose also a flat bottom but with rounded corners. However they leave a terrace-like scallop on non-flat surfaces.

A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters. We have broken these recommendations down into material categories so you can make better decisions with how to.

They are less prone to chipping and generally have a longer tool life. 45U_RB - Bull Nose End Mill. The words end mill are generally used to refer to flat bottomed cutters but also include rounded cutters referred to as ball nosed and radiused cutters referred to as bull nose or torus.

30m MS2SBR0020S04 maintained high R accuracy. I have some ball end mills that I hardly ever use. 164 2-flute flat end mill.

Bull-nose End Mill. The most important aspect of milling with carbide end mills is to run the tool at the proper rpm and feed rate. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish.

Bull nose inserts are used in finishing when milling flats and sides. Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines. With better heat and wear resistance than high-speed steel these cobalt steel end mills can run at higher speeds and provide better performance on hard material such as iron hardened steel titanium and tool steel.

DESCRIPTION005 SQ EM 2FL 015. Flat end mills will cut flat areas with no scallops. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

1100 2-flute flat end mil. Corner Radius End Mills. There are a few ball end mill uses the big one being the ability to produce free form curves.

A corner radius end mill has a small radius on each corner the radius is typically 020 030 045 etc. Bull-nose end mills. Request a Test Today.

The most common are flat end mills and ball end mills. Ball End Mills are very durable and come with an array of. Scientifically Proven to Give You a Competitive Advantage.

These have a flat bottom but rounded corners so you can have a filleted inner corner while also. Milling Speeds and Feeds Charts. Ball Nose Milling Without a Tilt Angle.

You can see bull-nose end mills as a transition between flat and ball-nose ones. What is a ball end mill used for. FLUTES FLUTE DIAMETER FLUTE length shank diameter neck diameter overall length reach length LBS neck length behind flutes corner radius end type Flat WEIGHT lbs coating.

End Mill Bagian Bagian Dan Jenis End Milling Cutter Pt Yakin Maju Sentosa

What S The Difference Between Flat Ball Angle Radius End Mill

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Common Types Of End Mills 3 1 Voxel Based Mrr Expression Of The Download Scientific Diagram

Hanzel 5 Things Should Know How To Selecting End Mill

Hanzel 5 Things Should Know How To Selecting End Mill

End Mills The Essential Beginners Guide

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Xcan 2 Flute Ball Nose End Mill 4 6mm Shank Cnc Router Bit Carbide End Mill Spiral Milling Cutter Milling Cutter Aliexpress

End Mill Bagian Bagian Dan Jenis End Milling Cutter Pt Yakin Maju Sentosa

Jual Tool 12mm 4 Flute Milling Cutter Tungsten Carbide End Mill Jakarta Barat Lazata Shop Tokopedia

Jual End Mill Carbide Leo Ball Nose 6mm Flat 12mm Hrc 45 55 100mm Long Shank 12mm Endmill Milling Cnc Indonesia Shopee Indonesia

Three Common Shapes Of End Mill Tool Engin Altintas 200112 Download Scientific Diagram

General Tool Geometry And Surfaces Of The Various End Mills A General Download Scientific Diagram

End Mill Itu Apa Sih Fungsi Dan Kegunaannya Pt Indonesia Surya Sejahtera

Skip To Content Robbjack Corporation Menu Solutions Spotlight Making The Switch To Aluminum For Lightweight High Performing Automotive Applications Only Robbjack S A1 303 Met This Machining Requirement Where Over 20 Other Toolmakers Failed See

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing

Square End Mills Grainger Industrial Supply

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool